The Albany Tomato Company has been an on-again, off-again project for the past five years. I definitely bit off more than I could chew when I started it, and looking back now I can't imagine what I was thinking. I wanted to build it (my first scratchbuilt structure) to such a level of detail that it would win "best in show" during a modeling contest. I intended to scratchbuild all the windows, add an interior vignette scene at the loading dock, and perfectly paint and weather it. What was I thinking?

The past three months have been spent in painting it. I really wanted to rush and "finish it" but that would be a sure fire way to ruin what I spent so much time on. So I took it slow. In my opinion, it is the billboard artwork (as shown in this 1963 shot) that really make it special. So I wanted custom decals made. But the only image available had telephone wires running through it, the bottom was obscured by the reefer, and it was taken at an skewed angle. I would never be able to use it as is. I needed to reach out to a custom decal maker to see if he could produce graphics for the side of the building. Lance Mindheim, an excellent modeler who makes broad use of decals himself, referred me to William Brillinger at Precision Design Company.

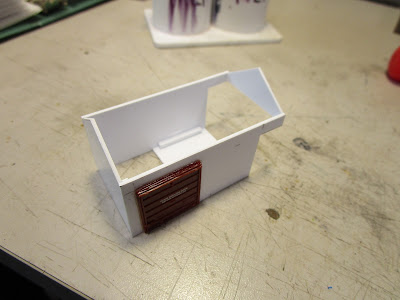

Bill took my image and played with it for a bit, filled in missing pieces, and adjusted the size of it until we had artwork that worked for me. He was fast, responsive, and honestly went beyond what I was expecting. He emailed me some test proofs and I mocked them up on the side of the building to make sure they fit. We decided that I would paint the white border (and black background) behind the image instead of using a white border on the actual decal, which I think made sense. I then washed the building to remove five years' worth of dirt, dust, grease, etc. and spray painted the building with several light coats of white primer paint. This hid any marker lines and pencil smudges, and filled in some of the minute cracks and gaps. I left it alone for a week, and then masked the area of the sign that was to remain white.

Next, I sprayed the rest of the building with Krylon Colormaster "Pimento" red paint. Part of the red seeped under the masking tape onto the white, but I expected this. I also noticed some spots that I missed with the red so I had to repaint those areas with more light coats, and that added time. Either because I was stalling or playing it very safe and letting the paint cure, I was waiting 7-21 days between spray sessions.

But, it was starting to look like something! I was getting excited.

I actually intended to use a darker shade of red on the non-billboard sides, similar to how the building looked in 1984. However, I changed my mind. I suspect this dark, purplish color shift is mostly to due to the age of the slide film and since I can' t be sure what color it should be I stuck with red and heavily weathered the sides to darken them.

I next brush painted the roof gray. I avoided spray painting it because the masking wouldn't have been perfect anyway with all the corners and edges, and I would still have needed to touch it up. I chose Tamiya "Light Gray" (XF-65) paint and went around the edges of the roof tops, then the insides, and then the roof itself.

It went pretty quick, though I needed to add several coats to build it up. The Tamiya paint is a bit thick and sets quickly, and if you go over an area you painted only a couple of minutes ago it will lift it up a bit. It also smells strangely sweet, like fruit cereal. I have noticed that with all Tamiya paints I have used, though I somewhat enjoy it.

I then laid the building on its side and used a microbrush to paint the edges of the roof trim pieces. I tried various positions to hold my wrist perfectly in line with the part I was painting, but some sides had trim at three different levels which complicated things.

I then started painting the various windows and doors. To give myself a steady hand rest, essential when using a fine brush to paint straight lines such as the window sills, I set the building on top of my garbage can and laid my elbow on my desk. It worked really well, though I had to rotate the building four times for each window to get perfect coverage. I didn't trust myself to paint towards myself, and always wanted to paint left to right, so round and round the building went for each window.

It took four sessions (each about 10-15 minutes) to get it all done. I took frequent breaks to clear my head and also wash my paint brush. It wasn't too bad, though my "assistant" Clover would sometimes get in the way. She is trained to go under my desk, sit at my feet, and get a treat. In this picture, you can tell which step she is at!

Painting the larger doors wasn't difficult either, but I can now confidently say that Pimento red paint is a terrible primer for the gray I was using. The larger doors required multiple coats for good coverage, yet I was careful not to pool it on as I didn't want it to bubble or slop around.

The roof windows were done the same way, except that those middle windows were especially tough to paint. The upper window sashes took some real maneuvering with the brush to apply the gray without hitting the red bricks. From all sightline it is nearly impossible to see if they are gray or red, so I erred on the side of caution.

The lower windows on the right corner had a solid styrene backing (meaning, I wasn't going to glaze it) so I had to treat them differently. I first painted everything inside the window opening gloss black and let it cure fully. Then, I picked out the window frame itself in gray. The black sort of looks like dark glazing... I had no other good options. If I were installing this on a layout there definitely would be bushes in front of them!

Two coats of gray paint on the roof gave it a mottled appearance with obvious brush strokes. However, I think that will come to be an advantage when weathering it as perhaps it will look like a brush-applied tar mixture.

I also used a small brush and some more red and white paint to clean up the edges of the billboard area on the side. Eventually, I had to say "when" and just stop because it was an otherwise endless battle of adding red, then adding white, then adding red, and so on.

Boy, let me tell you it was a really stupid idea to glue the air conditioner units onto the roof before painting. I should have left them off, as they need to be painted silver. I had to carefully do it with a tiny brush and it wasn't easy. Thankfully, the silver went over the white and red overspray paint easily and covered well with one coat.

I used a fine brush to pick out the pipes and some of the other small details with silver too. Here I had to compromise, as I mostly focused on the edges of the pipes facing out and ignored the sides of the pipes. From a foot away it looks great, but upon closer scrutiny you can see the sides are red. There is just no way I can paint them perfectly silver without getting silver on the red walls. Perhaps I should have waited to glue them on, but in the prototype pictures they don't show up so I assumed that they were painted the same color as the side of the building. Weathering will help tone them down. I also painted some of the roof vents silver, but left others gray for contrast and to make it look like the A/C units on the larger building were updated more recently than the older, gray ones.

Two and a half months after I started painting the building, I finally bit the bullet and worked on the black and white area where the billboard advertisement will go. I cut fresh edges of blue masking tape and embossed them down with a toothpick into the brick mortar joints. For the area by the loading door awning, I did the best I could but assumed that I would need to do some touchup there.

I then lightly brushed on two coats of flat black paint. I avoided spray paint because I wanted more control along the tape joints.

Despite my best efforts, the black leaked beneath the tape. Instead of trying to touch it up with a brush, I instead ordered some Microscale white 1/8" wide decal stripes (#PS-1-1/8"). In preparation for them, I sprayed this wall with Glosscote and the rest of the building including the roof with Dullcote.

I then applied the white decal stripes, which worked pretty good. Because I had to lay the building on its side and its center of gravity made it tipsy, I clamped it to my workbench.

Finally, it was time for the custom billboard decals. I trimmed around their exterior with scissors but they were still pretty large. I then soaked it in water and it just wrinkled up. The water might have been too hot, and/or I let it soak too long. Grrr. Thankfully, I had ordered two sets of decals for just this situation. The second set was soaked for less time, in lukewarm water, and it went on pretty good. One edge rolled over on itself and I had to fix it, but overall I was very thankful about the whole process. Then, lots of light coats of Microsol were brushed on to help the decal snuggle down into the brick mortar joints.

I am pretty well pleased with it. Compare to the picture in the book on the right. William Brillinger did an excellent job with artwork.

It was time to weather the model, and I didn't want to screw it up right at the last step! I had earlier mounted some scrap brick sheet to a piece of styrene and painted it the same red as the building, and figured I would use it as a test area for various shades of oil paint wash. I mixed black and brown oil paint in mineral spirits and applied it to one area of the test piece. Too dark, so I watered down some of it in a separate container. Too light, so I added more of the concentrated stuff. Just right.

Note to self: in the future, I should look into weathering powders as they would have probably been perfect for something like this.

Three sides and the roof were weathered, but the billboard side I left clean. The weathering looked blotchy so I smoothed some of it out a day later while it was still wet with paper towels. Honestly, it looks better and more subtle than in the pictures.

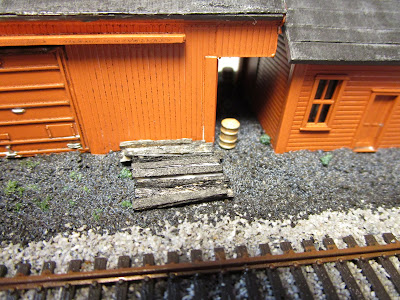

With the weathering done, there was only one detail left: the front entrance stairway. The steps were built months ago but needed to be painted, yet I held off on this at the time because I planned to drill holes and insert a railing, and that railing had to be built. I was going to use a commercial railing from Walthers but it didn't include a 90-degree bend, and modifying it would be as much work as fabricating one from scratch. So, I drew up some sketches of what I needed and started to cut brass rod to solder it up.

I quickly realized that I could build one faster from styrene. It wouldn't be as strong, but likely it would be cleaner and certainly easier. It is delicate, but it only took me 30 minutes to build so if I break it I can make it again. Instead of drilling holes and gluing it in, I designed it to attach to the outside edges of the stairs.

During construction I added lots of extra cross pieces and bracing while assembling it, which made it sturdy as I added piece by piece. Then, once it cured I cut away everything I didn't want and I had my railing. I attached it to the stairs and it was done. It only needed to be painted.

The stairs were then spray painted red, the handrails were picked out in silver, and I applied weathering washes and drybrushing to make it look dirty and a bit rusty.

Once I attached the railing to the front of the building, the workers could get in to start processing tomatoes.

The HVAC units on the roof were drybrushed with brown and rust colored paints, and I applied a black wash to the grill areas. You can see in this shot how the black oil paint washes made the gray painted roof look like old, weathered brushed tar. At least I think so.

The windows were glazed with clear styrene, attached with canopy glue. I wish I could have used real glass but trying to cut and fit odd sizes into the window areas was just a non-starter.

I wasn't sure what to do next about the windows. They were nice and clear, but that just let everyone look inside and see nothing but empty space (and pen marks, and paint overspray, and styrene bracing, etc.) I considered painting the backs of the windows black, but that seemed a bit permanent and if I didn't like the look I was stuck. So, I spray painted some index cards black, cut them into strips, and lightly tacked them in place on the inside with tacky glue. They work, but now the building looks a bit fake. Spraying the inside surfaces of the glass with Dullcote is another option I might consider, but for now I am okay with this. Access to the inside is easy, and prying off the index cards which are minimally attached wouldn't be difficult.

The last thing I did was add a little mini scene on the roof. I used Walthers crates and Preiser pallets, along with some stripwood, to create a hang-out for the employees to go on their breaks. I may later add figures, but for now this is it. And, I am happy to say, the building is finished.

I am very proud of what I built. Though it wasn't intentional, I looked at the drawings again this morning and realized that some of them are dated 4/23/2015. I remember waking up early (something like 4AM) the morning after visiting a friend's layout and being inspired to start work on this project. That means it took six years exactly from start to finish.

The structure is currently resting on a wooden base I made five years ago to protect the bottom edges of the building from cracking or breaking. I really need something nicer, but for now it works. However, the staircase is hovering above the ground and I need to add something underneath it to support it more.

The Albany Tomato Company was a long and winding road, filled with bumps along the way. I was way too ambitious at the start in attempting a complete scratchbuild with no experience. I had to frequently stop and take breaks to research things, and several times I left it alone for periods measured in years, not months.

But I can't wait to show my friend, who helped inspire and aided me on my building. I am sure he will be proud of me, and of it.

I only wish I had a place on my layout for the Albany Tomato Company!

PS: Here are two clippings from the old Knickerbocker Newspaper in which the Albany Tomato Company placed adds. The first is from 1951, and the other is dated 1/21/1969.